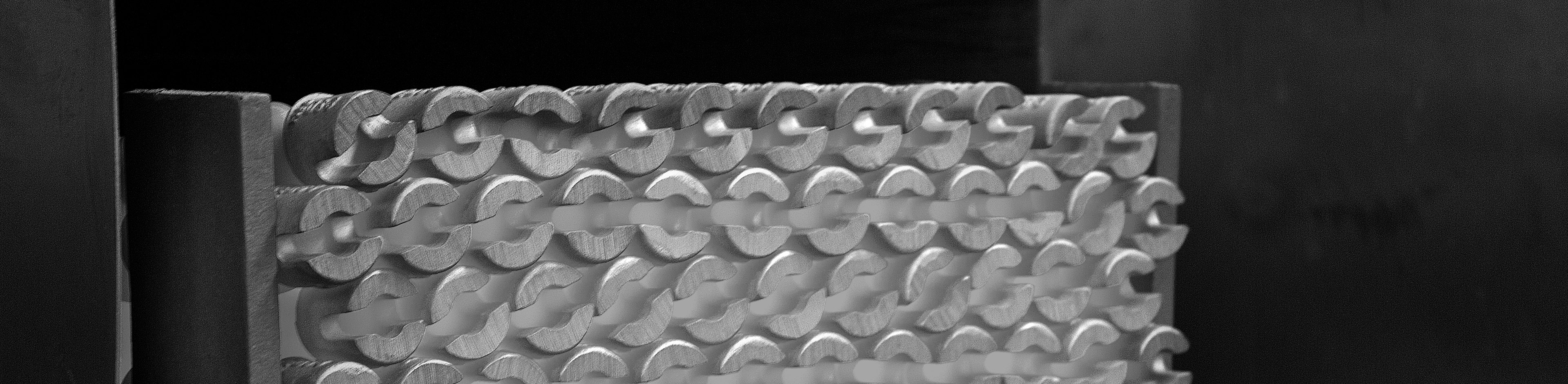

VAUTID Bi-metal castings

A VAUTID speciality for more than 20 years

Bi-metal castings have been a VAUTID speciality for more than 20 years. By using this technology, the advantages of different alloys are combined in one mould. As the first melt is not yet completely cooled during casting, the materials mix in the transition zone to form a reliable material bond.

For example, hammers for milling machines are produced with a head made of particularly wear-resistant material and a shaft made of a material with high tensile strength.

Wear-resistant castings are generally only to be machined with great effort and are not suitable for joint welding due to their carbon content. Therefore classical casting techniques often force compromises in the choice of materials. VAUTID bi-metal castings solve such conflicts,e.g. by casting weldable and machinable steel castings outside the wear zone.

This results in components of the highest quality that are easy to assemble and have a long service life. Our engineering specialists will be pleased to consult you on the selection of an efficient material combination and develop individual solutions for your components.

Please find more information on possible applications in our media center under: In focus – VAUTID Bi-metal castings.