Cement industry

Our solutions provide reliable, long-term wear protection for all types of equipment used in the cement industry. For every wear problem, VAUTID has a wide range of different solutions.

Here are some examples of VAUTID solutions used in cement works:

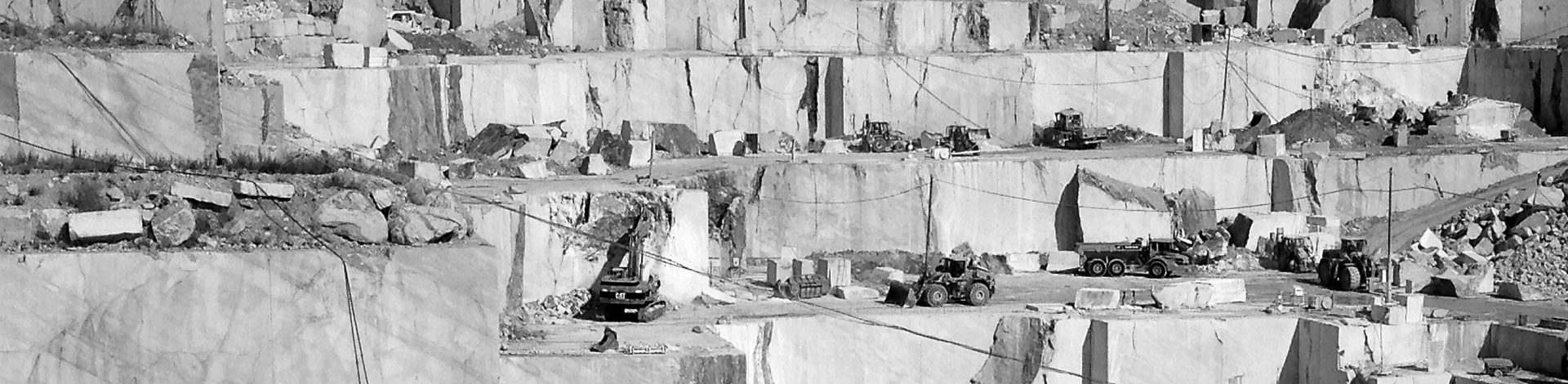

1. Quarrying

- Truck loading surfaces, conveying equipment and crushing plants, and shovels for excavators and wheeled loaders

2. Materials handling

- Feeder screws, material slides and funnels, the edges and liners of trough chain conveyors, side walls and scraper bars of belt conveyors

3. Crusher plants

- Liners, inlet funnels, crusher cones, crusher jaws and crusher hammers, impact mill beater bars and rotors

4. Mixing beds

- Mixing tools, portal scraper reclaimers, fittings

5. Mills

- Grinding rolls and grinding element outer liners, grinding tables, fans, separators, ring manifolds, pressure plates, covers and liners VAUTID can remanufacture rolls and tables either in the installed condition (in situ) or in the workshop

6. Silos

- Liners, fittings, feeding equipment, funnels and pipes

7. Preheaters

- Pipes, fans

8. Rotary kilns

- Material inlets, transfer stations, funnels

9. Clinker coolers

- Clinker cooling plates, grate facings, side wall wear protection

10. Clinker silos

- Liners, fittings, feeding equipment, funnels and pipes

11. Cement mills

- Grinding rolls and roll outer liners, grinding tables, fans, separators, ring manifolds, pressure plates, covers and liners VAUTID can remanufacture rolls and tables either in the installed condition (in situ) or in the workshop

12. Cement silos and packing stations

- Pipes, funnels, material slides and fittings