VAUTID 100T

For wear-resistant hardfacing layers and wear-resistant hardfacing layers operating at raised temperatures

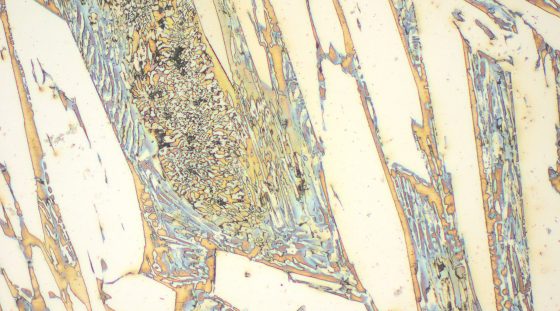

This member of the VAUTID 100 product family also embodies the extremely wear-resistant properties which are produced when chrome carbide is embedded within a stable matrix. Adding other alloying elements prevents the matrix from becoming destabilized by diffusion processes at temperatures over 350°C.

This raises the maximum operating temperature of VAUTID 100T to 550°C.

Recommended applications:

- Components which are exposed to temperatures up to 550°C.

- Components which carry a steady flow of abrasive media e.g. material slides, dust ducts, separators and ventilator fans.

- Components that operate in homogenous, abrasive materials e.g. coking plant equipment, sinter crushers, clinker breakers, feeder screws and sieves.

This welding alloy is also available as a VAUTID composite wear plate, produced using a special metal arc welding process (VAUTID VVP 100T).

Alloy

Carbides

Chromium carbides Cr7C3 2200 HV1

Typical microstructure VAUTID 100T

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).