VAUTID 60

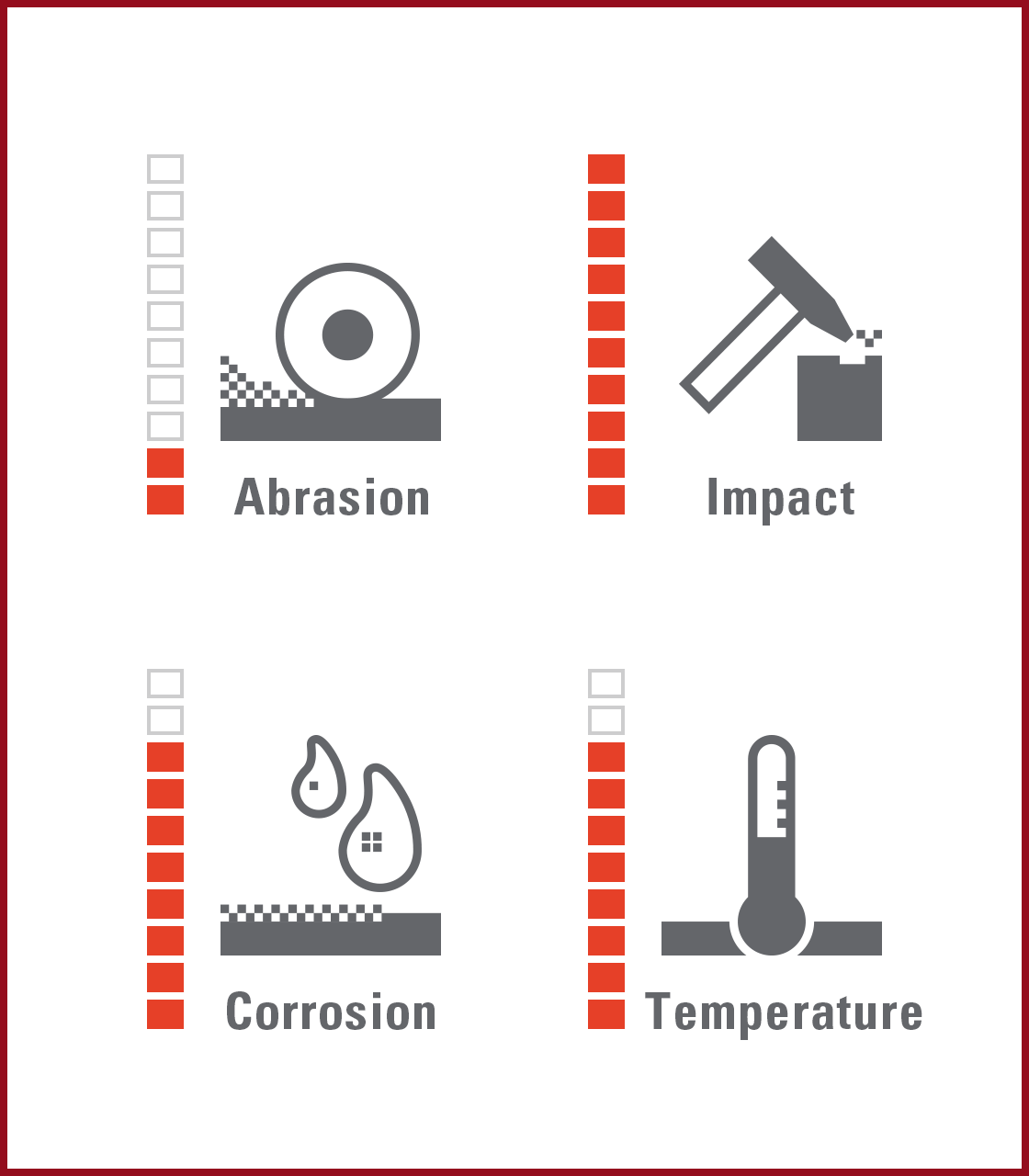

For applications involving severe impact wear and for buffer layers

Shock loadings have a surface work-hardening effect on alloys with a high manganese content. With its very high manganese content, VAUTID 60 demonstrates exceptional resistance to impact wear.

This alloy produces an extremely tough, crack-resistant weld metal which is non-magnetic and has a high tensile strength. The material is characterized by excellent compatibility with all weldable steels, and it can be flame cut. Hence VAUTID 60 is suitable for tough, pressure-tight buffer layers and for hardfacing components which are predominantly subject to impact stresses. It is also suitable for the remanufacture of components made from high manganese steel, e.g. hammers, beater bars and crushing rolls.

Recommended applications:

- Wear protection of components which are subject predominantly to impact stresses, e.g. impact heads, transfer points below fall pipes, and racks in blasting facilities.

- As a buffer layer between components made of weldable steel and wear-resistant VAUTID welding consumables.

Alloy

Typical microstructure VAUTID 60