VAUTID Ultra 305

A hardfacing welding consumable for exceptionally wear-resistant overlays, supplied as flux-cored wire

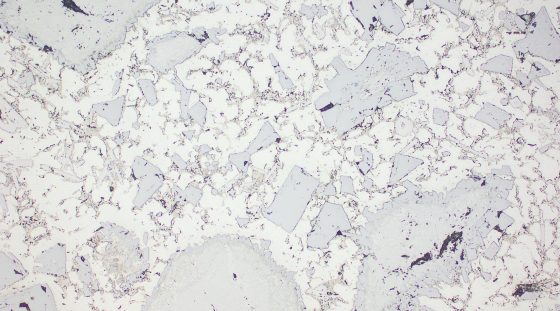

VAUTID Ultra 305 combines the exceptional wear resistance gained from using fused tungsten carbide (grain size 0.1 – 0.5 mm) with the ease of use of flux-cored wire . In addition, VAUTID Ultra 305 features an extremely tough nickel matrix, making it corrosion-resistant and capable of withstanding moderate impact without pitting.

Matrix hardness: ca. 550 – 650 HV10

Wear-resistant particles: ca. 2000 HV10

Recommended applications:

- For a straightforward method of producing extremely abrasion-resistant and corrosion-resistant layers using flux-cored wire.

- For protecting filigree areas of components, e.g. edges and points.

- Serial production parts which are subject to extreme wear and corrosion and are produced on automatic welding machines, e.g. scraper bars, feeder screw edges, drill pipe guides, mixer paddles, and ploughshares.

Alloy

Carbide

Tungsten carbides W2C 3000 HV1

Typical microstructure VAUTID Ultra 305

1 Carbide hardness is specified in the [HV] unit (Vickers hardness).